General Description

MINICAMS® is a fully automated, continuous, near-real-time air monitoring system. It was designed primarily for use in the U.S. Army's Chemical Stockpile Disposal Program as an automated chemical-vapor alarm system for monitoring of workplace air and other potentially contaminated in-plant zones, e.g., stack exhausts, ducts, filter banks, etc. It also works well for support of materials-penetration and permeation studies and many other laboratory or on-site test efforts involving a need to detect and quantify chemical vapors automatically and continuously. It provides audible, visible, and electrical alarm responses to toxic military chemical agent vapors, e.g., GB, VX, HD, etc., and to many other substances at any of a variety of regulatory threshold concentrations, e.g., TWA, MDL, PEL, etc. It also provides accurate vapor concentration readings at concentrations in the general vicinity of the preset alarm threshold. It was specifically designed to detect and accurately quantify the chemical agents and other volatile and semi-volatile compounds at far lower concentrations than most other chemical vapor monitors. MINICAMS is a readily transportable system that is designed to be set up and operated at fixed indoor locations or (under mild conditions) at sheltered outdoor monitoring stations, although instances of successful use in vehicles and other mobile platforms have occurred. It requires one or more compressed gases and a source of 117VAC electrical power for its operation.

Technical Description

MINICAMS® is based on collection of airborne chemical vapors on a solid sorbent or in a sample loop, thermal desorption or flushing of the collected vapors into a gas chromatographic (GC) column, separation of the sample constituents on the column, and detection by a sensitive GC detector. The available GC detectors include both universal (i.e., nonselective) detector types that respond indiscriminately to virtually all substances, and selective detectors that respond primarily to certain restricted classes of chemicals. The instrument cycles repetitively through a Sample Period, during which an air sample is accumulated, and a subsequent Purge Period, during which the collected sample constituents are separated, detected, and quantified. Total instrument cycle times can range from about 5 min to 20 min or more. When a selective detector is installed, MINICAMS delivers accurate quantification and detection limits in the parts-per-billion and/or parts-per-quadrillion range as a matter of routine, although the system can be reconfigured or "detuned" to cover almost any desired concentration range above these levels.

Evaluation Criteria

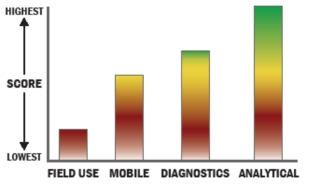

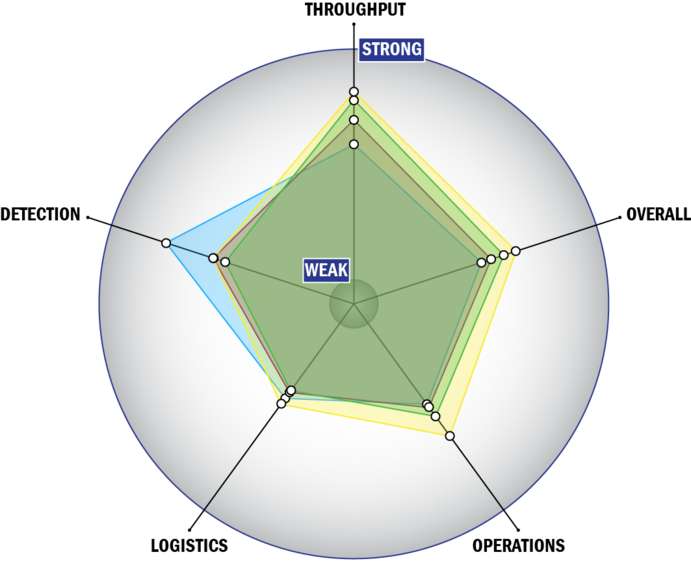

THROUGHPUT:

- Between 2 and 15 minutes for detection

- Continuous operation with no defined runs

- System is continuous and provides real time analysis with no defined tests/samples every 2 hours

- The system or device is currently fully automated

- Device or system is intended for multiple detection assays

- 0-1 solutions, buffer, eluents, and/or reagents

- Greater than 20 minutes is required for set-up

- Automatic detection

LOGISTICS:

- A day of training and technical skills are required

- Approximately the size of a carry-on luggage suitcase

- Between 5 and 25 kg

- Wired connections are available

- System or device has 110V electrical requirement

OPERATIONS:

- Can be used from 4°C to 41°C

- Between 6 months and 1 year shelf life

- Greater than 10 years expected life

- Results cannot be viewed in real-time

- The system or device is currently fully autonomous

- The system software is closed and not available for modification

- The system hardware is open and available for modification

DETECTION:

- Possible the system could receive 510K clearance, no current efforts at this time

- Possible the system could receive FDA approval, no current efforts at this time

- This system does not test liquids

- Excellent specificity. System has occasional false alarms under certain conditions (<2%)

- < 1x10-6 mg/m3

- Possible system could identify aerosolized chemical agent

- Possible system could identify liquid chemical agent

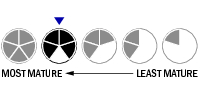

Top Tier

Top Tier Second Tier

Second Tier Third Tier

Third Tier Fourth Tier

Fourth Tier Bottom Tier

Bottom Tier