General Description

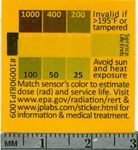

RADSticker is a peel-&-stick postage stamp sized (3cm x 3cm x 0.2mm, weight: 0.2g), instantly color developing, casualty dosimeter, can be carried 24/7 and always ready. Needs no power, has no electronics or moving parts, reliable, robust, rugged and useful for triaging radiation exposure information and medical treatment in a major radiological incident, such as a nuclear or dirty bomb explosion, nuclear power plant accident or mishandling of radiation sources. It can be applied on many objects and carried for a few years. RADSticker monitors 50–10,000 mSv. When exposed to ionizing radiation, the sensor of the dosimeter develops blue color instantly and the color intensifies as the dose increases. Radiation exposure can be estimated simply by matching the colors of the sensor with the adjacent color reference bars. If used as per instruction, RADSticker will not give false signals. The operating temperature range is from -30oC to 90oC. All essential information is printed on the front and back of the dosimeter. Additional information is provided in one page manual. The first generation of the dosimeter was field tested by DHS with 800 first responders for one year (http://www.tswg.gov/subgroups/cbrnc/detection/EML627SiradReport.pdf). It can be used by first responders (police, firefighters and emergency responders), military, hospital radiation workers, occupational and contract workers at nuclear power plants and the general public, especially in an event of a radiological incident.

Technical Description

The materials used for monitoring radiation are fine particles of colorless solid diacetylenes dispersed in a polymeric binder. Upon exposure to ionizing radiation, diacetylenes polymerize to blue colored polymers. The reaction is irreversible. As radiation dose increases more monomeric diacetylene molecules polymerize and color of the sensor intensifies.

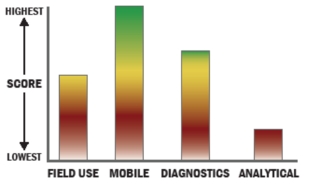

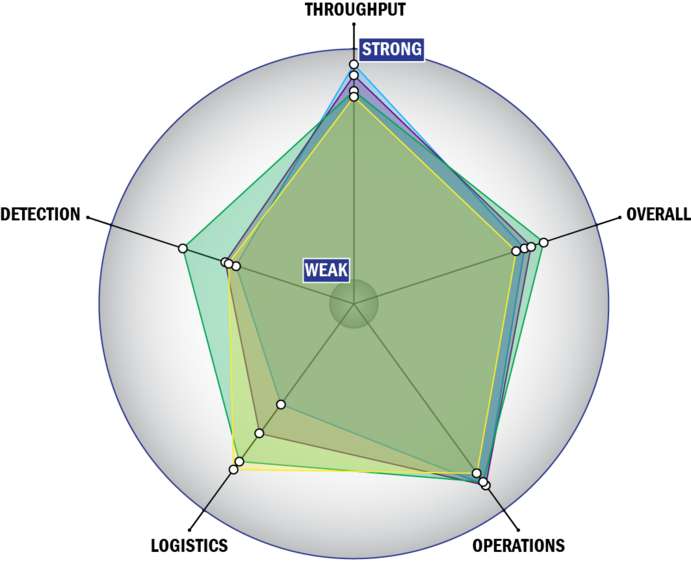

Evaluation Criteria

THROUGHPUT:

- Detection is instantaneous

- 1 sample, single test/sample per run

- System is continuous and provides real time analysis with no defined tests/samples

- The system or device is currently fully automated

- Device or system is designed for a single use

- 0-1 solutions, buffer, eluents, and/or reagents

- 0 components

- No set-up of the system is required

- Automatic detection

LOGISTICS:

- Very brief (minutes-hours) training and minimal technical skills

- Less than 1 kg

- This system is not capable of transmitting data

- There is no electrical requirement

OPERATIONS:

- Can be used from < -21°C to > 42°C (All temperatures)

- Performance is not influenced by relative humidity

- Greater than 3 years shelf life

- Results can be viewed in real-time

- The system or device is currently fully autonomous

DETECTION:

- Possible the system could receive 510K clearance, no current efforts at this time

- Possible the system could receive FDA approval, no current efforts at this time

- This system does not test liquids

- Superior specificity. System has a false alarm rate approaching zero (~0%)

- Only total dose and dose rate

- System is used for personnel detection

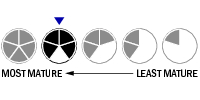

Top Tier

Top Tier Second Tier

Second Tier Third Tier

Third Tier Fourth Tier

Fourth Tier Bottom Tier

Bottom Tier