General Description

ASAP V is an automated CBRNdetection and identification system for mail rooms and similar installations. The system can be configured to meet a customer's exact threat deterrent needs. These systems are typically used in a negative pressure room equipped with a down draft table and can handle thousands of pieces of mail per hour. Incoming mail is separately tested for radiological threats. Next, an air sampling module in the system continuously samples air drawn into the downdraft table while mail is being shaken or opened over the table's perforated top surface, providing appropriate samples to the biological identification components. The air stream to the sampler is connected to chemical sensors to detect chemical threats. Sampling is a continuous process that goes on until processing of a batch of mail is complete, whether it is a few or several hours. The bio threat identifier can be set up to detect and identify from two to four threat agents. Periodically, or on demand, a concentrated aqueous sample is transferred from an air sampler and in fifteen minutes the system will identify the presence of any of the pre-selected agents, and automatically notify the operator if the mail is clear or if a pathogen has been detected.

Technical Description

The ASAP V is modular in design and is constructed to customer requirements.

Available sensors include:

- Two different ion-mobility spectrometers detect chemical warfare agents, toxic chemicals and explosives

- The SASS 2300 air sampler + Raptor fluoroimmunoassay bio-identifier.

- A sensitive gamma ray detector that detects and identifies radiological threats.

The ASAP II uses R's SASS 2300 wetted-wall cyclone to concentrate particulates from the air into a water sample. Patented technology measures the volume of water in the cyclone and continuously replenishes evaporative losses, allowing unlimited collection periods. In operation, the SASS 2300 samples air continuously and transfers particulates into a secondary water phase of about 4 to 5 ml volume. Transfer of the sample from the SASS to the Raptor is fully automated as are analyses, based on "sandwich format" fluoroimmunoassays taking place on the surface of injection molded polystyrene waveguides. The waveguide has a monolayer of capture antibody immobilized on its surface. Excitation light is injected into and fluorescence emission is collected from the waveguide.

Evaluation Criteria

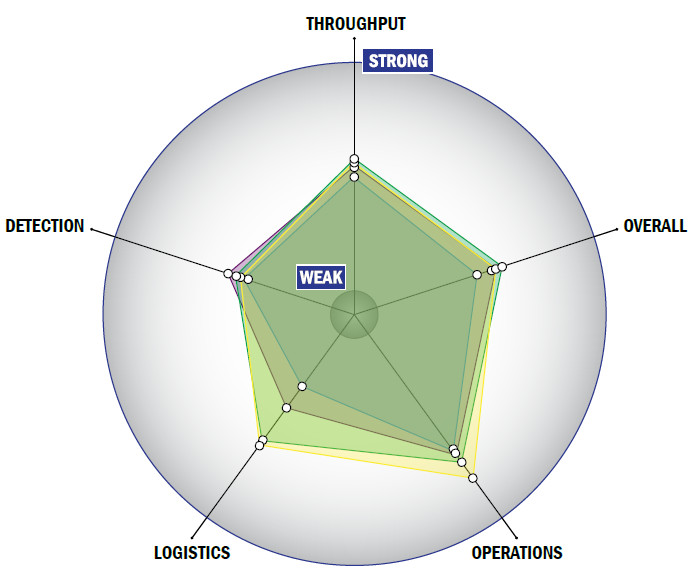

THROUGHPUT:

- Between 2 and 15 minutes for detection

- Multiple samples, multiple tests/sample per run

- Less than 32 samples every 2 hour

- The system or device is currently semi-automated

- Device or system is intended for multiple detection assays

- 5 or more solutions, buffer, eluents, and/or reagents

- 1 component

- 10-20 minutes is required for set-up

- 1-2 steps are required for detection

LOGISTICS:

- Very brief (minutes-hours) training and minimal technical skills

- Larger than a home dishwasher

- Between 25 and 50 kg

- Wireless and wired connections are available

- System or device has 110V electrical requirement

- The device is not intended for portable use

OPERATIONS:

- Can be used from 4°C to 41°C

- Components must be stored at 4°C

- Performance is not influenced by relative humidity

- Between 1 to 6 months shelf life

- Greater than 10 years expected life

- Results can be viewed in real-time

- The system or device is currently fully autonomous

- The system software is open but modification requires licensing

- The system hardware is closed and not available for modification

DETECTION:

- Possible the system could receive 510K clearance, no current efforts at this time

- Possible the system could receive FDA approval, no current efforts at this time

- Greater than 250 μl

- Excellent specificity. System has occasional false alarms under certain conditions (<2%)

- 10,000-100,000 CFU per mL

- Greater than 100,000 PFU per mL

- 1-10 ng per mL

- > 1x10-3 mg/m3

- Only dose rate

- Down to background level radiation for dose rate

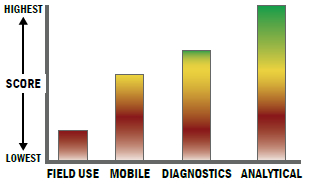

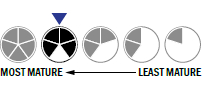

Top Tier

Top Tier Second Tier

Second Tier Third Tier

Third Tier Fourth Tier

Fourth Tier Bottom Tier

Bottom Tier